Commitment to Excellence in Quality and Technology #

Kun Huang is dedicated to advancing our expertise and staying at the forefront of technology to ensure consistently high-quality standards in polyurethane foam manufacturing. We recognize that exceptional products are the result of a robust development process, advanced production technology, and transparent information management. Our commitment to Company Wide Quality Control (CWQC) standards is central to our mission to be a leading supplier of PU foam materials, enhancing both our reputation and competitiveness.

Principles of Company Wide Quality Control (CWQC) #

Transparency of Information

Accurate and valuable information is the foundation of effective quality control. We collect and analyze internal data from design, development, and production, while also engaging with relevant departments. Customer feedback regarding products, materials, and end-user experiences is carefully considered. Through discussion, evaluation, and analysis, we strive to deliver products and services that align with market trends and meet high standards of quality.

Collaborative Supervision

Quality management at Kun Huang is a shared responsibility. Rather than limiting quality assurance to a single department, we encourage all employees to take ownership of quality outcomes. This collaborative approach fosters a culture of responsibility, ensures accurate information sharing, and unites the team in pursuit of common objectives.

Sustainable Development

Our vision for sustainable development extends beyond meeting customer requirements in design, development, production, and quality. Senior management is actively involved in implementing comprehensive policies that nurture a collaborative environment. We motivate every team member to contribute wholeheartedly to the continuous improvement of materials, products, and services.

Quality Assurance and Continuous Improvement

We are committed to deepening our understanding of production processes, composite technologies, and industry standards. By prioritizing customer requirements and building strong relationships, we are able to offer both new and existing product solutions. Customer feedback is integral to our process, guiding ongoing improvements and ensuring our products are recognized in the market for their quality and reliability.

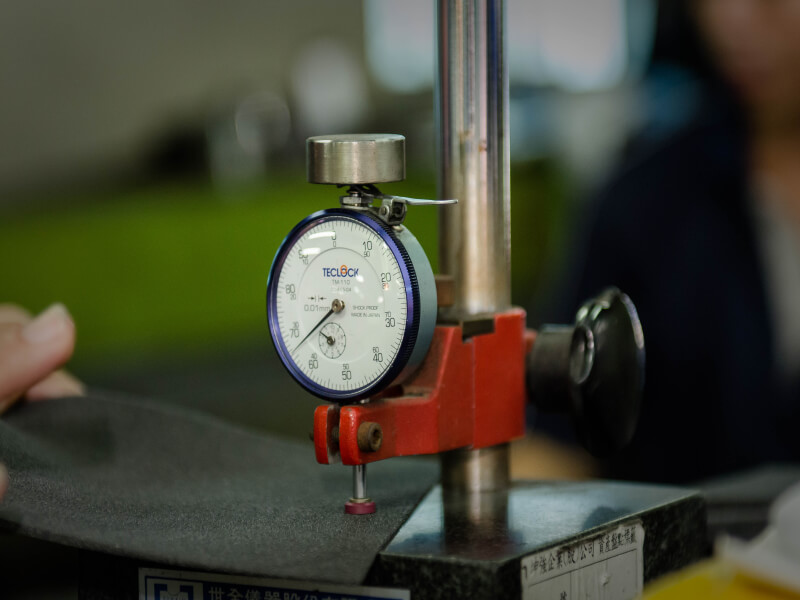

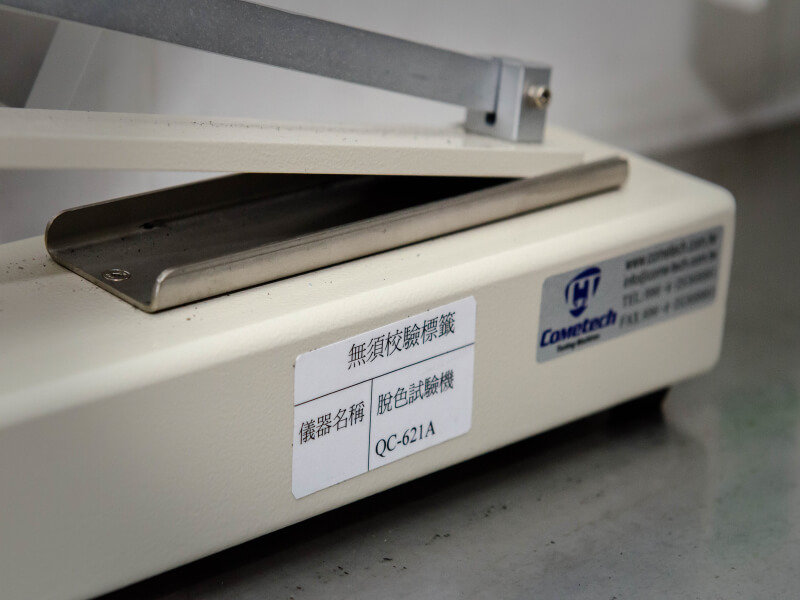

Laboratory and Quality Inspection Capabilities #

Kun Huang maintains a dedicated laboratory and quality inspection area to ensure that both sample and mass-produced foam materials meet stringent specifications. Our testing capabilities include:

- Hardness assessment

- Rebound measurement

- Compression set evaluation

- Tensile strength testing

- Breaking stress analysis

- Elongation testing

- Crock meter testing

All tests are conducted in accordance with customer requirements, supporting our commitment to delivering high-quality polyurethane foam materials.

For more information about our company and products, please visit our official website.